Design of Experiments

User defined

functions

Scale-Up Module

Fast computing times

PSI – Paderborner Spritzgiesssimulation

The Paderborn Injection Molding Simulation - PSI is a joint research project in which about 20 industrial companies and the KTP of the University of Paderborn are currently involved. The aim of the project is the ongoing further development of the PSI simulation software of the same name, which can be used to calculate plastics processing operations on single-screw plasticizing units. PSI enables the rapid and comprehensive assessment of machine behavior and thus creates the possibility of optimizing barrel and screw configurations as well as process parameters. This goal is achieved by implementing predominantly analytical and closed-form equations. Computationally intensive numerical methods are avoided as far as possible.

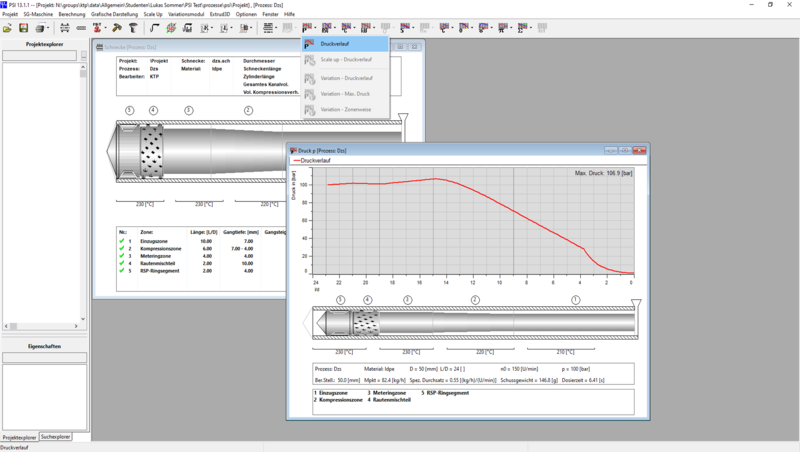

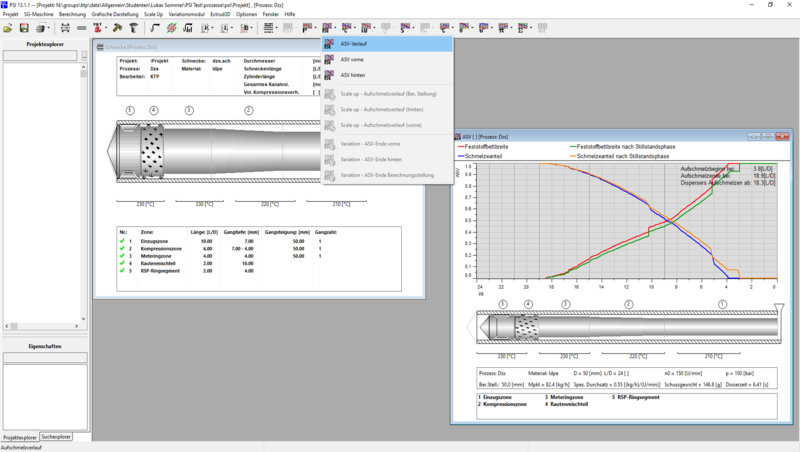

Simulation results

The results of the simulation calculations can be output graphically in the form of diagrams as well as in tabular form. The graphical output is designed to show the progression of a variable over the screw length. This type of plotting makes it possible to evaluate individual screw zones. Based on these findings, simple modifications can then be made to the screw design if necessary. Fig. 1 and Fig. 2 show examples of the pressure and the melting profile of such a simulation calculation.

In order to be able to compare and evaluate the effect of different influencing variables, a so-called variation module has been implemented in PSI. In this variation module, all variables that have an influence on the process can be varied. All variations of the process are calculated and can be displayed simultaneously in a so-called multi-graph following the calculation.

Features in detail

In addition to the actual calculation, PSI offers further program functions that support the user during optimization.

Design of Experiments

As a further function, PSI offers a tool for statistical design of experiments (DoE). This can be used to define the relevant target variables and influencing variables. Depending on the choice of statistical model, the matrix for the reduced experimental design is then automatically created and each operating point is calculated. The correlation of the results is then described with a regression model. This allows the user to graphically evaluate the result and easily determine the optimal operating point for the screw concept under consideration.

Scale Up

As a further aid, PSI includes a scale-up module. This allows the user, for example, to transfer processes determined on small laboratory extruders to a production plant of larger design.

User defined functions

It is thus possible to have your own functions calculated in the form of user-defined functions. Values calculated internally by PSI can be used here to determine your own company-specific characteristic values. This facilitates the calculation of these values in that, for example, the material characteristic values are always selected for the respective state in the process.

Fast computing times

The software is based on an analytical calculation algorithm, which guarantees extremely short calculation times. In contrast to complex finite element simulations, even complicated geometries are calculated quickly in just a few seconds.

Technical details

Supported barrel designs

- Smooth bore barrels

- Grooved bush barrels

- Degassing barrel

Supported screw sections:

- Feeding, Compression, Metering, Barrier Maillefer, Barrier, Decompression, Wave, PIN section

- Conical -, Maddock-, Troester , Spiral-, Cylindrical shearing section

- Cross hole, Faceted mixing and toothed mixing section

- NRV-ring segment

How can I purchase the software?

Our software products are not subject to a classic licensing model. Rather, we aim to advance the development of the software together with our partners. This means that we conduct joint research projects in two-year terms, in the context of which the rights of use for the respective software product are agreed.

PAM - Paderborn

Material database

The Paderborn Material Database is a software tool for managing and evaluating material data in the field of plastics technology.

Contact

F. Knaup, M.Sc.

Project Manager REX/PSI

Kunststofftechnik Paderborn gGmbH

Universität Paderborn

Pohlweg 47-49

D-33098 Paderborn

Tel.: 05251/60-3837

E-Mail: info@ktp-software.de

Contact

F. Knaup, M. Sc.

Project Manager REX/PSI

Kunststofftechnik Paderborn gGmbH

Universität Paderborn

Pohlweg 47-49

D-33098 Paderborn

Tel.: 05251/60-3837

E-Mail: info@ktp-software.de