Rückblick Praxisworkshop – Einsatz von Rezyclaten in der industriellen Produktion

On Monday, June 14, 2021, this practical workshop took place at Zukunftsmeile 2 in Paderborn.

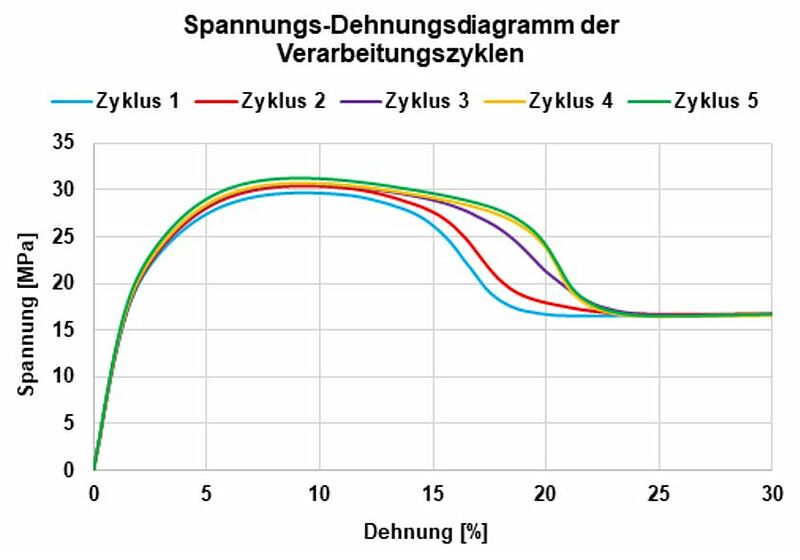

Recycled materials, especially post consumer recycled (PCR) materials, are excellent in terms of mechanical properties, but inferior to virgin materials in terms of the decorative quality of the surface. Here, many customers are not willing to compromise on quality. Even if post-industrial goods have clear advantages over PCR in terms of cleanliness and grade purity, there are also limitations here if, for example, rejects show significant material degradation or coating.

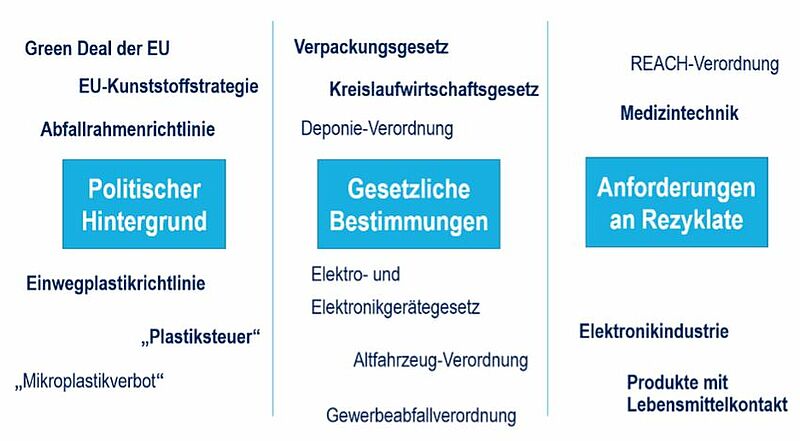

Dr.-Ing. Matthias Hopp from the Institute of Plastics Technology at the University of Paderborn outlined the political and legal conditions and requirements that can be expected in the field of plastics and recyclates in the coming years. In particular, he emphasized the increase in the recyclate content required by the amendment to the EU's Green Deal for the packaging, automotive and construction sectors from 2022. In concrete terms, this means that additional industries will have to prepare for the use of recyclate and that this demand will also have to be met by recyclers.

In the discussion with company representatives, challenges to the use of recyclate included fluctuating quality as well as impurities, price and often color. These factors make the use of recyclates difficult for certain fields of application or, in some cases, impossible. The requirements of the REACH regulation also set a high standard for recyclate purity, which is difficult to achieve in some cases. Overall, there are many reservations on the part of user companies about actually using recyclates.

Axel Baranek from FVH Folien Veredelung Hamburg and Jochen Ebbing from Lobbe Industrieservice GmbH gave an overview of the current status of plastic recyclates in terms of quality, quantity and supply capability. Due to the current supply bottlenecks for virgin material last year, the sales market for recyclates has changed completely and could be expanded significantly. Customers were more open to the use of recyclates. As a result, the quality of the products produced by FVH could prove itself.

Even though there are currently no legal requirements for the use of recyclates, most of the participating company representatives were of the opinion that recyclate quotas will become a relevant topic for them in the next few years.

Existing processing techniques such as sandwich injection molding or multi-component technology can be used well for processing recyclates. For example, the recyclate can be used as a core component and laminated with a top layer of virgin material. This makes it possible to cover up the lower surface quality of the recyclates. In addition, processing the same type of plastic from recyclate enables good compatibility with virgin material.

The topic of product development / design for recycling was also addressed. Recycling-friendly product design makes it possible to significantly increase the quality of post-consumer recyclates (PCR) from the yellow bag. At the same time, the proportion of plastics that must be sent for thermal recycling can thus be minimized.

A need for research was formulated with regard to the availability and recycling of engineering plastics such as PA and PC.

Conclusion: the plastics processing industry definitely has a need for plastic recyclates, provided they are of high quality and consistent quality can be guaranteed.

Ein Forschungsbedarf wurde hinsichtlich der Verfügbarkeit und der Kreislaufführung von technischen Kunststoffen wie PA und PC formuliert.

Fazit: Die kunststoffverarbeitende Industrie hat durchaus einen Bedarf an Kunststoffrezyklaten, sofern diese qualitativ hochwertig sind und eine gleichbleibende Qualität garantiert werden kann.

Link: Innozent